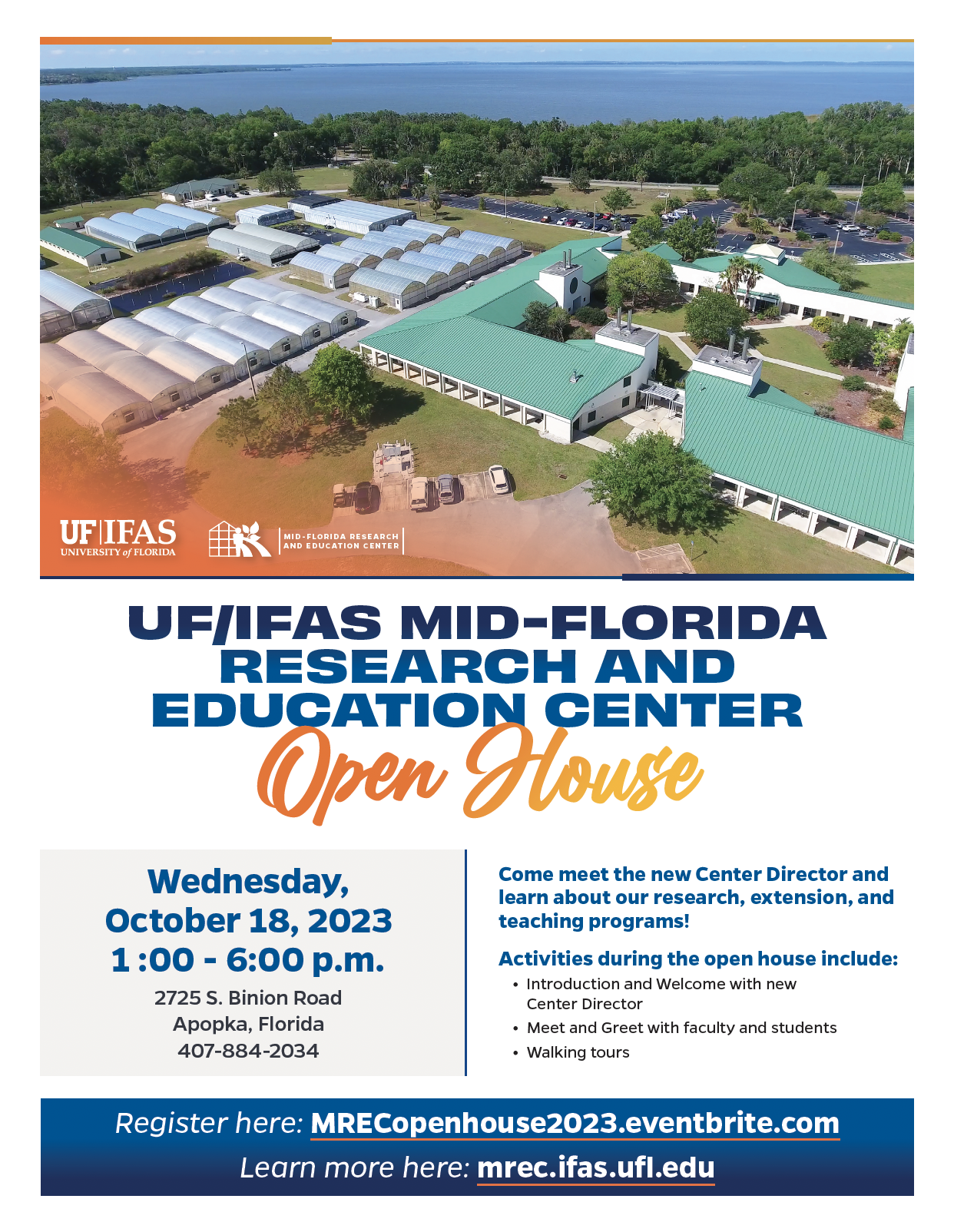

The Mid-Florida Research and Education Center is one of 12 University of Florida Institute of Food and Agricultural Sciences (UF/IFAS) Research and Education Centers. Located in the heart of Florida’s greenhouse and nursery industry in Apopka, Florida, MREC focuses on lifestyle horticulture: profitable yet environmentally responsible production and use of high-value horticulture plants and plant products to satisfy demand driven by consumer tastes, preferences, and wellness.

The link in the photo does not work. Please click on the following link: MRECopenhouse2023.eventbrite.com to register.

The link in the photo does not work. Please click on the following link: MRECopenhouse2023.eventbrite.com to register.